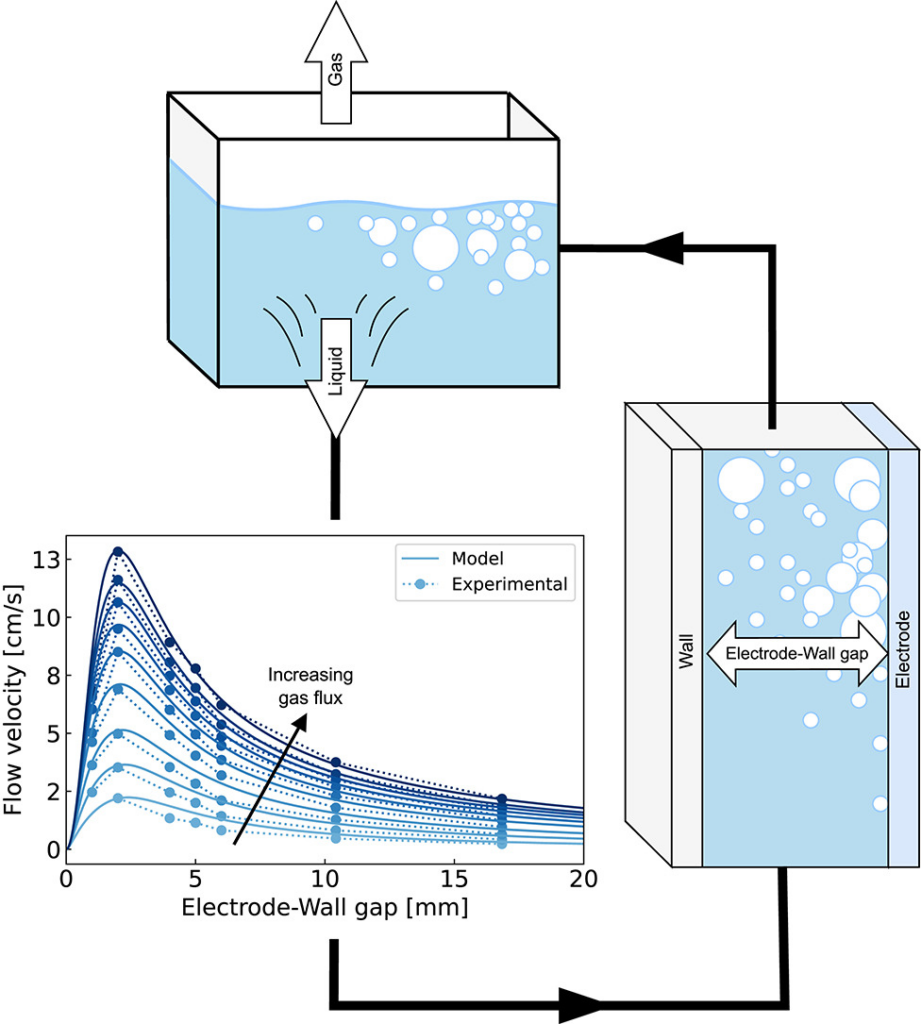

In many electrolysers, including water electrolysers for the production of green hydrogen, gas bubbles are created that can be used to drive natural electrolyte circulation. These bubbles rise due to buoyancy, setting the liquid electrolyte into motion. Normally, pumps are used to induce this electrolyte flow, which moves heat out of the cells. However, by designing an electrolyser well, pumps are no longer needed.

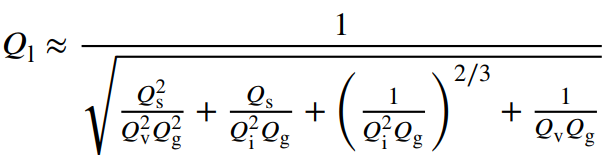

We developed a model that accurately predicts the liquid flow rate (Ql) as a function of the gas flow rate (Qg), matching our in-house experiments very well:

It includes the most important physical effects, including:

- viscous losses in the downcomer (Qv)

- inertial losses due to bends and turbulence (Qi)

- bubble slip (Qs)

From this equation we derived expressions for the optimal electrode-wall distance that, for example, maximizes the electrolyte flow rate. In this way our model will allow for the future design of more efficient and pump-free electrolysers.