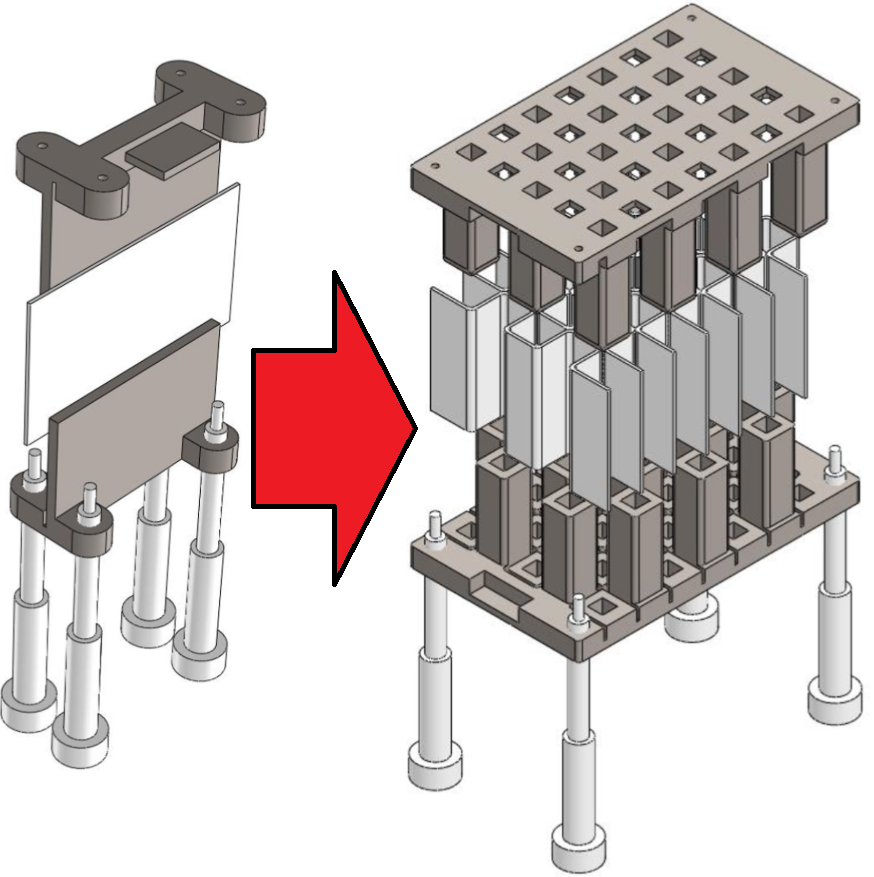

In many electrochemical stacks, a large fraction of the total volume goes to flow channels that transport reactants and products into and out of the cell. In the conventional bipolar ‘sandwich’ design, each flow channel borders only a single electrode. Pim van der Stighel, then a second year BSc student, in a process engineering & thermodynamics class suggested an alternative in which each electrode faces four other electrodes – sufficiently novel and promising to file a patent application together. Another team of BSc students, in co-supervision with Hadi Rajaei, made this into a metal-3D-printed prototype producing hydrogen. Our recent paper shows that electrolysers for hydrogen production can be easily made up to 1.5-2 times less voluminous, while for fuel cells or flow batteries the volume of the flow channels can even be reduced by a factor 3-4.

Worried about the practicality of making this on a large scale? A second patent was filed for a design with the same advantages, but conveniently manufactured from corrugated plate electrodes.

Exit ‘sandwich’ – enter ‘checkerboard’ stacks